Still waiting for the thicker SS material to arrive.

In mean time I made a turbine of even thinner 0.5mm stainless steel...which works fine as a test turbine. I have put a thicker plain steel washer in the centre to stabilize the flimsy turbine disc though...

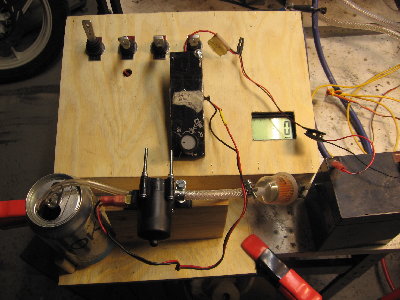

I fixed the fuel leak and run it successfully on pure diesel. I used a multipurpose windscreen washer fluid pump as fuel pump. I control the speed with a simple homemade pulse width modulation circuit based on the 555-IC. The pump/injection needles are over dimensioned so the throttle is VERY sensitive.

Its amazing to se how quick the thin turbine blades heat up during acceleration in the low rpm region and how fast they cool down once higher speed is reached!

I think the combustion is fluctuating slightly but it does not seem to present any problem

As always, make sure to wear head phones while watching the video clip, it is realy enlightening! Lots of information hidden in the sound of a engine.

Youtube video testrunning the motor on diesel:

http://www.youtube.com/watch?v=_sORDfes9Sc

- Picture shows both the propane and the diesel fuel system. They both inject into the vaporizing sticks. Click on the picture and have a closer look!

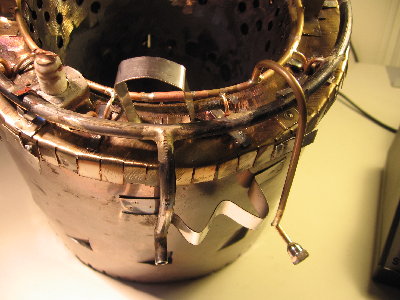

- Experimental turbine with holow blades for cooling air. It functions as a turbine but not very well.

- Fuelpump and pulse width controller, diesel in the 33cc aluminium-can...

- Perfectly uggly welding!

- New thin turbine spot welded onto thicker steel disc.