Calculations... double checking with the pro's

Moderator: Mike Everman

-

larry cottrill

- Posts: 4140

- Joined: Sun Oct 05, 2003 1:17 am

- Antipspambot question: 0

- Location: Mingo, Iowa USA

- Contact:

re: Calculations... double checking with the pro's

Just a few comments ... yes, I have been paying attention ...

Evidence of positive thrust, even without measurement, IS important - it is extremely easy to make a nice noisy "ramjet" that turns out to be basically a thrustless burner. If you are getting thrust that exceeds the drag of the air going through, that is proof that you are at least getting some pressure gain in the diffuser, which is what you're after. Note that on a flying engine, the thrust would have to FAR exceed both internal drag and the drag of airflow around the engine shell. That excess drag would EQUAL the non-engine drag of the airframe (wings, fuselage, tail planes) at the design airspeed.

I have grave doubts about the effectiveness of an engine that shows no sign of heating at the chamber, or at least throughout the exhaust nozzle. The point is not to get an impressive exhaust flame, but to have massive combustion in the chamber, so that the nozzle can develop maximum expansion - expansion after the flame exits the nozzle does nothing for you. If you're getting a good noisy burn but throwing a long tail flame, I would suggest slowly backing off the blower, inch by inch, until the flame "pulls" back inside the chamber. Note that this may happen fairly suddenly at some point. Then, check to make sure the flame is staying aft of the diffuser. I'll bet you'll find that thrust is maximum at that point.

If your jet is running right, and you know you're getting positive thrust, the next thing to do is measure the actual flow speed at the intake - you want to know how fast the engine should be going to operate correctly! You could set up a simple Pitot tube arrangement to do this, or even get hold of an old aircraft air speed indicator - you wouldn't have to worry about the 'static port' connection (keep it open, not blocked!) as long as the inlet tube is positioned right at the engine intake and there's significant space between the tube inlet and the blower outlet. Positioning the tube near the center of the intake would be ideal, to avoid any effects of the intake rim.

Congratulations to all !!!

L Cottrill

Evidence of positive thrust, even without measurement, IS important - it is extremely easy to make a nice noisy "ramjet" that turns out to be basically a thrustless burner. If you are getting thrust that exceeds the drag of the air going through, that is proof that you are at least getting some pressure gain in the diffuser, which is what you're after. Note that on a flying engine, the thrust would have to FAR exceed both internal drag and the drag of airflow around the engine shell. That excess drag would EQUAL the non-engine drag of the airframe (wings, fuselage, tail planes) at the design airspeed.

I have grave doubts about the effectiveness of an engine that shows no sign of heating at the chamber, or at least throughout the exhaust nozzle. The point is not to get an impressive exhaust flame, but to have massive combustion in the chamber, so that the nozzle can develop maximum expansion - expansion after the flame exits the nozzle does nothing for you. If you're getting a good noisy burn but throwing a long tail flame, I would suggest slowly backing off the blower, inch by inch, until the flame "pulls" back inside the chamber. Note that this may happen fairly suddenly at some point. Then, check to make sure the flame is staying aft of the diffuser. I'll bet you'll find that thrust is maximum at that point.

If your jet is running right, and you know you're getting positive thrust, the next thing to do is measure the actual flow speed at the intake - you want to know how fast the engine should be going to operate correctly! You could set up a simple Pitot tube arrangement to do this, or even get hold of an old aircraft air speed indicator - you wouldn't have to worry about the 'static port' connection (keep it open, not blocked!) as long as the inlet tube is positioned right at the engine intake and there's significant space between the tube inlet and the blower outlet. Positioning the tube near the center of the intake would be ideal, to avoid any effects of the intake rim.

Congratulations to all !!!

L Cottrill

re: Calculations... double checking with the pro's

I don't know if this relates really... but I do know that the higher I turn the blower up, the smaller the flame gets.

Also, on last night's run, the ramjet really wasn't too hot... but then again, I did wait to touch it for a minute or so, and it WAS pretty cold out... I hope to try again today, once with the tank inverted, once with the tank regular, and some different positions with the stinger. I really hope to see the test stand jerk forward a bit... that would be VERY encouraging!

Also, I do notice, that running it without a blower, 90% of the flame comes out the back, I assume this is a good sign, correct? all the gas IS blowing perpendicular to airflow.

PS: about holding the stinger, that's not a problem, it's shaped in an S shape, so my hand is out of the way, I'm also wearing a faceshield and welding gloves, so I'm not TOO worried...

PPS: if I don't produce much thrust, what would be a way to increase that? create more pressure? (shrinking the hole in the flameholder) or decrease it? Also, does the legnth of the diffuser have anything to do with it?

PPS: oh, Larry, your comments are always helpful! well... maybe after reading them a few times and pondering over them a while... ;) even if you aren't paying attention, you have built a good ramjet... (Correct me if I'm wrong there...)

PPS: oh, and if I run it tonight, I'll add some calcium nitrate to make the flame nice and pretty! That stuff makes fire a nice, deep red.

Also, on last night's run, the ramjet really wasn't too hot... but then again, I did wait to touch it for a minute or so, and it WAS pretty cold out... I hope to try again today, once with the tank inverted, once with the tank regular, and some different positions with the stinger. I really hope to see the test stand jerk forward a bit... that would be VERY encouraging!

Also, I do notice, that running it without a blower, 90% of the flame comes out the back, I assume this is a good sign, correct? all the gas IS blowing perpendicular to airflow.

PS: about holding the stinger, that's not a problem, it's shaped in an S shape, so my hand is out of the way, I'm also wearing a faceshield and welding gloves, so I'm not TOO worried...

PPS: if I don't produce much thrust, what would be a way to increase that? create more pressure? (shrinking the hole in the flameholder) or decrease it? Also, does the legnth of the diffuser have anything to do with it?

PPS: oh, Larry, your comments are always helpful! well... maybe after reading them a few times and pondering over them a while... ;) even if you aren't paying attention, you have built a good ramjet... (Correct me if I'm wrong there...)

PPS: oh, and if I run it tonight, I'll add some calcium nitrate to make the flame nice and pretty! That stuff makes fire a nice, deep red.

Lasers, jets, and helicopters HURAH!

re: Calculations... double checking with the pro's

Did a quick run outside (and it's COOOLD out there!) Unfotunatly, no improvements.... I still can't get it to move... I sense it wants to, but it just wont... I DO have a lotta space in that flameholder, I personally think it should be more restrictive, but, what do you guys think?

Oh, and I thought up a name,

The CHEAT-A-JET

Oh, and I thought up a name,

The CHEAT-A-JET

Lasers, jets, and helicopters HURAH!

-

Zippiot

- Posts: 1190

- Joined: Tue Nov 15, 2005 7:55 pm

- Antipspambot question: 0

- Location: california

- Contact:

re: Calculations... double checking with the pro's

The ramjet section of pulse-jets.com is from an article (was it practical ramjet design?) says that in a subsonic ramjet, the flameholder should not take up more than 30% of the chamber...can you calc how much yours is taking up I would assume the closer you get to 30 the better...

Was it your jet you could see thru, that may be the problem, although it can sustain ram operation it may not be efficient...

Was it your jet you could see thru, that may be the problem, although it can sustain ram operation it may not be efficient...

Sailing Student- How do I know if my life jacket is tight enough?

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

re: Calculations... double checking with the pro's

oh, well in that case... I should be fine, mine has got to be somewhere pretty close to that! I thought it was more...

Anyways... I really don't know if the doughnut shape is the best anyways, but, I went with the idea and made it! perhaps the "next" one will work a bit better...

Anyways, at least the spectators don't know the difference! ;)

PS: does anyone think I should chop the diffuser down a bit? I probably will, unless someone stops me... (remember the diffuser is pretty huge!)

Anyways... I really don't know if the doughnut shape is the best anyways, but, I went with the idea and made it! perhaps the "next" one will work a bit better...

Anyways, at least the spectators don't know the difference! ;)

PS: does anyone think I should chop the diffuser down a bit? I probably will, unless someone stops me... (remember the diffuser is pretty huge!)

Lasers, jets, and helicopters HURAH!

-

larry cottrill

- Posts: 4140

- Joined: Sun Oct 05, 2003 1:17 am

- Antipspambot question: 0

- Location: Mingo, Iowa USA

- Contact:

re: Calculations... double checking with the pro's

thecheat -

I do think that cutting back your diffuser would be good. My gut feel (no evidence for it, really) is that a LOW SPEED ramjet should have about equal intake and exhaust nozzle cross-section. Having the diffuser too long (really meaning, too high an area ratio) is just trying to get an unrealistic pressure gain from a low speed air source. (Like trying to force a nut when the thread is crossed ;-) You can cut it back somewhat gradually, looking for the "best running" condition. The problem with this is that you don't know you've gone too far until ... you've gone too far. I certainly wouldn't cut it back more than where the intake is the same diameter as the outlet end of the exhaust nozzle.

L Cottrill

I do think that cutting back your diffuser would be good. My gut feel (no evidence for it, really) is that a LOW SPEED ramjet should have about equal intake and exhaust nozzle cross-section. Having the diffuser too long (really meaning, too high an area ratio) is just trying to get an unrealistic pressure gain from a low speed air source. (Like trying to force a nut when the thread is crossed ;-) You can cut it back somewhat gradually, looking for the "best running" condition. The problem with this is that you don't know you've gone too far until ... you've gone too far. I certainly wouldn't cut it back more than where the intake is the same diameter as the outlet end of the exhaust nozzle.

L Cottrill

re: Calculations... double checking with the pro's

well... unfortunately, when I made the new nozzle, the outlet turned out at about the same size... so it's already there, which, could be the problem...

in that case, should I shorten the nozzle some? I made it a little bit longer than the old one... and if worst comes to worst I could hacksaw the current one off, and weld the old one in place *groan* After cleaning the metal blobs out of it that is...

in that case, should I shorten the nozzle some? I made it a little bit longer than the old one... and if worst comes to worst I could hacksaw the current one off, and weld the old one in place *groan* After cleaning the metal blobs out of it that is...

Lasers, jets, and helicopters HURAH!

-

Zippiot

- Posts: 1190

- Joined: Tue Nov 15, 2005 7:55 pm

- Antipspambot question: 0

- Location: california

- Contact:

re: Calculations... double checking with the pro's

What is the in^3 of your intake entrance and at the point where it dumps into your combustion chamber?

Lets say it goes from 1.5 inches to 3 inches, that means it goes from 7.06 in^3 to 28.27 in^3, expansion ratio for that intake would be around 4.

Measure the diameter [radius] of your intake entrance, exit, cc and do the same with the nozzle. The intake and exhaust shoudn't be the the "same" the exhaust should be slightly larger. Dont remember the ratio for that though.

Lets say it goes from 1.5 inches to 3 inches, that means it goes from 7.06 in^3 to 28.27 in^3, expansion ratio for that intake would be around 4.

Measure the diameter [radius] of your intake entrance, exit, cc and do the same with the nozzle. The intake and exhaust shoudn't be the the "same" the exhaust should be slightly larger. Dont remember the ratio for that though.

Sailing Student- How do I know if my life jacket is tight enough?

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

re: Calculations... double checking with the pro's

ok, well... first off (I really don't understand what you want me to do with the numbers.... I'll just post the dimensions here) I'll just name off the dimensions.

diffuser entrance dia-4.5cm

diffuser legnth-14.5cm

diffuser exit dia-7.18cm

CC legnth-11.5

Nozzle legnth-6cm

nozzle exit dia-4.6cm

PS: over 60% of the flame IS inside the CC... just another tidbit that might help diagnose the problem...

diffuser entrance dia-4.5cm

diffuser legnth-14.5cm

diffuser exit dia-7.18cm

CC legnth-11.5

Nozzle legnth-6cm

nozzle exit dia-4.6cm

PS: over 60% of the flame IS inside the CC... just another tidbit that might help diagnose the problem...

Lasers, jets, and helicopters HURAH!

-

Zippiot

- Posts: 1190

- Joined: Tue Nov 15, 2005 7:55 pm

- Antipspambot question: 0

- Location: california

- Contact:

re: Calculations... double checking with the pro's

So with 4.5 entrance its got an area of 15.90cm^3 (for the rest of this post I will not type ^3, I hate doing that)

Exit area is 40.49

So you intakes expands 2.55 in 14.5cm

...

I would try for something closer to 3.5-4

Mine had around 5.8 expansion in 3 inches (7.62cm)

Expansion isnt everything, you need a smoothe flow and for the jet to take in a bunch of air.

Its not all math, I aint so good with the numberz...guess and check is as good as any calculations at this point.

But you can design the jet around your expansion ratio, once you have picked that you can determine how much fuel to use and how long of a combustion chamber. Gaseous fuels can use a shorter CC than liquids, as liquids needs to vaporize before combustion. How much longer, I don't know...

So you are using propane with an expansion ratio of 2.55 at a diameter of 7.18. I would say that your CC can be as short as 6cm with a good flameholder. The flameholder slows the air down to combustion speeds, if you cant keep the flame inside the CC mess with the flameholder. Try a finger-type or even a baffle/finger. Pics can be found on the main pulse-jets.com site. So with a good flameholder and a 6cm CC, lets design a nozle. Shouldn't be as long as the intake and should not close down to nearly the same size. If your intake is 4.5cm and your exhaust is 4.6, try widening the exhaust but dont hack it off, try to make a new cone.

Exit area is 40.49

So you intakes expands 2.55 in 14.5cm

...

I would try for something closer to 3.5-4

Mine had around 5.8 expansion in 3 inches (7.62cm)

Expansion isnt everything, you need a smoothe flow and for the jet to take in a bunch of air.

Its not all math, I aint so good with the numberz...guess and check is as good as any calculations at this point.

But you can design the jet around your expansion ratio, once you have picked that you can determine how much fuel to use and how long of a combustion chamber. Gaseous fuels can use a shorter CC than liquids, as liquids needs to vaporize before combustion. How much longer, I don't know...

So you are using propane with an expansion ratio of 2.55 at a diameter of 7.18. I would say that your CC can be as short as 6cm with a good flameholder. The flameholder slows the air down to combustion speeds, if you cant keep the flame inside the CC mess with the flameholder. Try a finger-type or even a baffle/finger. Pics can be found on the main pulse-jets.com site. So with a good flameholder and a 6cm CC, lets design a nozle. Shouldn't be as long as the intake and should not close down to nearly the same size. If your intake is 4.5cm and your exhaust is 4.6, try widening the exhaust but dont hack it off, try to make a new cone.

Sailing Student- How do I know if my life jacket is tight enough?

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

re: Calculations... double checking with the pro's

sorry.... but I'm still a little confused....

ok, so the intake expands the air 2.55x, lowering pressure, boosting speed (correct me on this) It then hits the flameholder, pressure goes up, speed goes down = combustion

Then, directly after the flameholder the pressure again decreases, and the speed goes back to the previous speed, expansion of gasses makes it go faster, and poof... er... whoosh, you've got a net gain of velocity.

What's confusing me is, firstly, why to the third power? that's volume (3D) not area (2D) I assume you would use 2D for this... Secondly, could you draw up a picture of yours to give me a visual? pictures are good!

Also, if you've got a decreased pressure out the exhaust, how does that affect your jet? with mine I've got roughly the same pressure (not including the gas) I assume this is what's affecting my jet?

fourth, what happens if you don't even reduce the end of the jet?

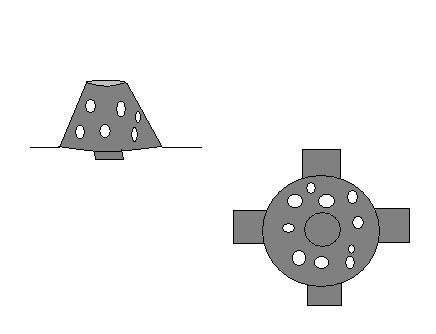

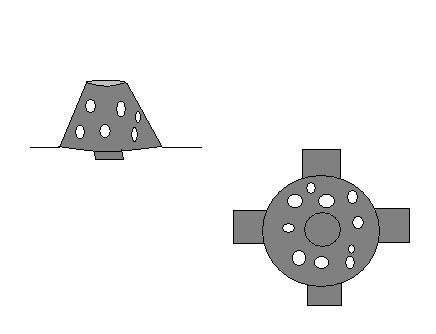

Finally, what do you think of my newest idea for a flameholder? :D Original as always! I call it the cheezegraterbaffler cone

Despite the bad illustration, you think it would work? it's a flat headed cone with holes drilled in the sides...

EDIT: Oh, and how would I go about making the nozzle wider? it would be easiest to hack some off of the end... rather than hack the hole cone off and weld a new one on... maybe I could make some sorta "quick exchange" system...

ok, so the intake expands the air 2.55x, lowering pressure, boosting speed (correct me on this) It then hits the flameholder, pressure goes up, speed goes down = combustion

Then, directly after the flameholder the pressure again decreases, and the speed goes back to the previous speed, expansion of gasses makes it go faster, and poof... er... whoosh, you've got a net gain of velocity.

What's confusing me is, firstly, why to the third power? that's volume (3D) not area (2D) I assume you would use 2D for this... Secondly, could you draw up a picture of yours to give me a visual? pictures are good!

Also, if you've got a decreased pressure out the exhaust, how does that affect your jet? with mine I've got roughly the same pressure (not including the gas) I assume this is what's affecting my jet?

fourth, what happens if you don't even reduce the end of the jet?

Finally, what do you think of my newest idea for a flameholder? :D Original as always! I call it the cheezegraterbaffler cone

Despite the bad illustration, you think it would work? it's a flat headed cone with holes drilled in the sides...

EDIT: Oh, and how would I go about making the nozzle wider? it would be easiest to hack some off of the end... rather than hack the hole cone off and weld a new one on... maybe I could make some sorta "quick exchange" system...

Lasers, jets, and helicopters HURAH!

-

Zippiot

- Posts: 1190

- Joined: Tue Nov 15, 2005 7:55 pm

- Antipspambot question: 0

- Location: california

- Contact:

re: Calculations... double checking with the pro's

cm^2.................see told you numbers get me!

Next time I'll sleep, although I do like the xfiles at 3am

As the air goes through the intake it is expanded, SLOWING IT DOWN. As it slows it increases pressure, but this slowing of the air and pressure gain is not usually enough to slow 200 mph winds to combustion speed. Combustion speed is only a few meters per second. That is why we need the flameholder, it slows the air enough to get it to proper combustion speed.

Flameholder looks good, I would make it a 6 finger (instead of 4) and drill a few more holes. Maybe have the fingers swept back so that the air still flows well yet is slowed.

For an example, and I am sure my math is wrong please correct me someone:

200 mph winds expanded 2.55 times slow to 78 mph. Combustion speed is a few meters per second, so lets pretend it is around 10mph just to get a nice clean number. 10 mph is roughly 4.4meters per sec, roughyl...

So we need to get the airspeed down from 78 to 10, no easy task.

Next time I'll sleep, although I do like the xfiles at 3am

As the air goes through the intake it is expanded, SLOWING IT DOWN. As it slows it increases pressure, but this slowing of the air and pressure gain is not usually enough to slow 200 mph winds to combustion speed. Combustion speed is only a few meters per second. That is why we need the flameholder, it slows the air enough to get it to proper combustion speed.

Flameholder looks good, I would make it a 6 finger (instead of 4) and drill a few more holes. Maybe have the fingers swept back so that the air still flows well yet is slowed.

For an example, and I am sure my math is wrong please correct me someone:

200 mph winds expanded 2.55 times slow to 78 mph. Combustion speed is a few meters per second, so lets pretend it is around 10mph just to get a nice clean number. 10 mph is roughly 4.4meters per sec, roughyl...

So we need to get the airspeed down from 78 to 10, no easy task.

Sailing Student- How do I know if my life jacket is tight enough?

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

-

tufty

- Posts: 887

- Joined: Wed Dec 24, 2003 12:12 pm

- Antipspambot question: 0

- Location: France

- Contact:

Re: re: Calculations... double checking with the pro's

I think you're wrong; flame propagation speed doesn't really come into it.Zippiot wrote:As the air goes through the intake it is expanded, SLOWING IT DOWN. As it slows it increases pressure, but this slowing of the air and pressure gain is not usually enough to slow 200 mph winds to combustion speed. Combustion speed is only a few meters per second. That is why we need the flameholder, it slows the air enough to get it to proper combustion speed.

The diffuser will slow down incoming air, and increase pressure. It's the pressure increase part that is good, not the speed thing, though. The flameholder will, in fact, speed up the air again (obviously, as you're going from area n to area 2n/3 for your 33% flameholder). However, the flameholder makes for a non-laminar flow, with loads of turbulent "pockets" of air; these pockets hold burning gas and provide an ignition source for the incoming fuel-air mixture.

Flame front speed is irrelevant, except that it has to be fast enough to burn the mixture while it is still in the chamber if we don't want to waste energy; the "burn" will be happening radially, backwards, forwards, all over the place in a chaotic mixture of burning, burned and unburnt fuel.

The major action of the flameholder is stopping the motor blowing itself out, it also helps with the fuel / air mixing

Of course, this may all be wrong.

Simon

-

Zippiot

- Posts: 1190

- Joined: Tue Nov 15, 2005 7:55 pm

- Antipspambot question: 0

- Location: california

- Contact:

re: Calculations... double checking with the pro's

Airspeed equates to cfm in a ramjet. There are minimum speeds, as the fuel/air needs to be shot out the back and so forth, but cfm is also a big factor.

Sailing Student- How do I know if my life jacket is tight enough?

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

Me- Can you breathe?

Sailing Student- Yes

Me- Then its too loose!

re: Calculations... double checking with the pro's

Ok, well now that I feel sufficiently dazed by what was just said... what would be a good ratio for the diffuser inlet to nozzle exit diameter?

Lasers, jets, and helicopters HURAH!