Page 1 of 1

Messerschmitt design?

Posted: Sat Oct 18, 2008 9:34 pm

by Charles

Hey all,

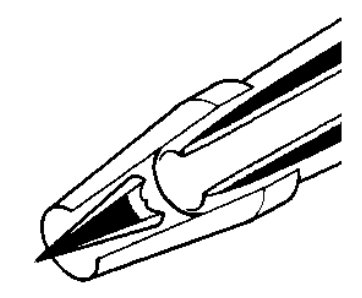

Was reading the forums main valveless page, and came across the Messerschmitt type of nozzle? Would anyone happen to have any images of know where I could find some info into this design?

- Messerschmitt.jpg (17.63 KiB) Viewed 12265 times

Thanks all

Charlie

Re: Messerschmitt design?

Posted: Mon Oct 20, 2008 9:56 am

by Vermin

There is information on one of the threads including a translation from the original data I don't recal where. The units were a pulse / ram dual mode unit.

Hope this helps. Mod 06 & 07 as attached.

V

Re: Messerschmitt design?

Posted: Mon Oct 20, 2008 7:20 pm

by Charles

Your awesome mate, you've even given me the actual dimensions

Thank you very much, I'm still bidding on Tig Welders on eBay theirs a black art to this and I've not even started learning!

Emailing a company about sheet metal being cut, with the shapes I've designed and what the dimensions in the images are, then I've the need to sort out about rolling the cones without an EnglishWheel? is that a device to bend or roll metal?

Gotta win this welder atm so I can get cracking on sorting out everything else

All the best,

Charlie

P.S: Darn I missed out by £10! darn not even the postage cost! Another one going in around 12-20 hours so I'll try again tomorrow, this is the forth day I've been outbid! D'oh!

Re: Messerschmitt design?

Posted: Mon Oct 20, 2008 8:37 pm

by tufty

Use this :

http://esniper.sourceforge.net/

Reminds me, I should get on with finishing the translation of all that stuff. I'm a lazy bugger. I might suggest that this is a fairly "ambitious" first weld, particularly WRT the variable geometry nozzle part, but also the perforated flameholder liner and - well - pretty much all of it.

Re: Messerschmitt design?

Posted: Mon Oct 20, 2008 10:00 pm

by hinote

tufty wrote: I might suggest that this is a fairly "ambitious" first weld, particularly WRT the variable geometry nozzle part, but also the perforated flameholder liner and - well - pretty much all of it.

Based on my years of TIG welding (and I'm still learning the skill) I'd recommend that you do a lot of practice--and even better, enroll in one of those college welding classes to get some good advice.

Buying a TIG welder won't make you one--any more than buying a camera makes you a photographer.

Practice, practice, practice...................................

Re: Messerschmitt design?

Posted: Tue Oct 21, 2008 9:40 am

by Vermin

To clairify some things, I think the 06 was strictly a pulse unit I don't recal the variable orifice in the transition between the primary and secondary CC.

If you want to learn how to weld start slow with mild steel, the TIG is a very versitile process but is very touchy with electrode control and type, as sugested take a course or do lots of reading and practice.

I would sugest startting with mild steel and keep the investment cost down untill the skill level increases SS is expensive, and not as forgiving.

For SS ensure you use a backing flux or the weld will be oxidized on the root side.

The M design appears to be a development from the IAME Escopetta perhaps you should try this one first and get the feel of starting and running first, I am assuming the Messershmit would be a touchy one to fire up (just a sugestion), plans attached.

Good Luck

V

Re: Messerschmitt design?

Posted: Thu Oct 23, 2008 11:20 am

by Graham C. Williams

Hi

As part of the NUDiS download package in the Tools section I have modelled a Type 06 motor with 100mm dia combustion chamber. The Type 06 model starts up easily and in the real world should run well statically. The Thrust is not spectacular but will improve with forward speed. The Induction plug is not at all critical to the motors static operation.

In contrast, the '07' motor shown above probably will not run well statically. Let's put it this way, when modelled in NUDiS with the dimensions as shown, the model will not run correctly under static conditions! It is my opinion that the Type 07 dims given are for a motor designed to have an initial velocity at start-up (not run statically). The location of the induction plug appears critical to starting as it forms part of the induction pipe length.

Finally, two more things. You'll notice, in each of the designs, that the induction pipe extends a little into the combustion space. If you plan to have a try at the small Type 06 motor don't do this, just have the induction pipe flush with the CC.

Both these motors are designed to be linear and run with there induction pipes pointing into the wind. They are curious designs; the only ones I've found that produce more thrust in there linear form than they do in a U bend form. (again, when modelling in NUDiS.)

Graham.

Re: Messerschmitt design?

Posted: Thu Oct 23, 2008 12:32 pm

by larry cottrill

Graham C. Williams wrote:The location of the induction plug appears critical to starting as it forms part of the induction pipe length.

Not only that, but the isometric view shows a conical outer shroud, which also forms part of this length. That is, the wave path splits forward and rearward where the wave emerges behind the streamlined recuperator "plug".

The negative wave reflection back into the chamber would come from the front and rear edges of this shroud, not at the annular gap behind the "plug". The timing of this negative reflection will be affected by forward velocity, too. I think Willy Messerscmitt must have thought, "Hey, if this was easy, anyone could do it." ;-)

Interestingly, the dimensioned plan does not show this shroud in place, so presumably the intake dimensions are correctly shown for its absence. Perhaps the shroud was an afterthought, with the intake pipe re-tuned (i.e. shortened) to accommodate it when it's used.

L Cottrill

Re: Messerschmitt design?

Posted: Thu Oct 23, 2008 12:58 pm

by Charles

You guys are very thoughtful and I thank you kindly for all your replies

I've laid off the eBay bidding for now in light of all your good replies and I've also contacted the local college and spoken to the held of welding dept or something, I've got a booking to meet him early next week and have a chat about what they can offer and all that.

I was asking loads of questions, but sadly the replies I would have got I would not have understood over the phone because I had never actually used a TIG welder in my life so redundant their really

Rather now I'm using my spare time to work out dimensions and building some cardboard 2D layouts and rolling them for the sizes I would like, or the models I'm looking at dimensions

Your all awesome, nice to meet you all and thanks again for all the nice replies and advice it's warmly received

Charlie

Re: Messerschmitt design?

Posted: Tue Feb 17, 2009 6:10 am

by No. 44

I've decided to build this engine in Solid Works in my free time and was wondering just how thick should the sheet metal be on this engine? I saw some dimensions around the CC but aside from that it didn't appear to include those. Maybe I missed them. I'm also curious about the most efficient placement of the spike and shroud. If this turns out nice enough I may have some of the welding students at the local tech college build one.

Re: Messerschmitt design?

Posted: Tue Feb 17, 2009 12:22 pm

by Graham C. Williams

The Full size -06 and -07 motors, at the top of this page, have the material thickness marked on the drawing.

The 100mm dia CC Type06 would probably be ok if built from anything between 0.5mm and 1mm depending upon skill level.

Graham

Re: Messerschmitt design?

Posted: Fri Feb 27, 2009 11:14 pm

by No. 44

Well I finally finished the engine in SolidWorks between lectures and homework and it's a heavy piece of equipment at about 28 kg with a wall thickness of .035 and all cast stainless. I'm not sure that would be needed or even a good idea but the materials can be changed easily enough at this stage.

Not much to look at and I'm not sure of what sort of numbers to expect since I haven't been able to get NUDiS to run on my desktop but it's a start. Now all I have to do is outsource the actuall assembly to some welding students. Hopefully they'll be desperate enough for something to put on their resume that they'll agree to a low price.