Moderator: Mike Everman

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Tue Feb 09, 2010 6:35 am

As odd as this may read, your program does

not incorporate the contribution of velocity drag in the simulation.

Also, here

Code: Select all

1040 LET dragforce = (1 / 391 * Cd * Frontarea * mph ^ 2) + RR

I was able to deduce and confirm the factor, 1/391, in the above line. You are going to regret doing things like this someday when you need to know 6 mos. from now where that factor originated.

F

Drag = ½ · ρ · A · V² · C

d

where ρ is defined as the density of air at sea level, i.e., 0.002377 slug/ft³

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Tue Feb 09, 2010 3:01 pm

Grey wrote:

Hmmmmmm.

And I thought that the velocity of the acting thrust came in at some point.

Or have I ( yet again ) missed something.

I should sleep some time this week.....

I think propulsive efficiency increases as the exhaust velocity begins to match the airspeed. But yes, it is dependant on the exhaust speed. I figured that was a given.

Forrest,

True, Drag doesn't directly contribute. Hmmm, that makes things more complicated. Was just using a comparison of forces. Rolling resistance isn't a constant either and is dependant on conditions, at least one can do a pull test with a scale and find a initial resistance.

Joe

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Tue Feb 09, 2010 5:01 pm

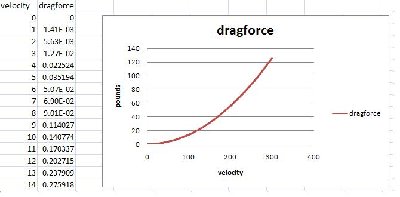

Yikes,not good

The mph is linear, I think there should be a faster rise and a slight plateau as thrust becomes equal to drag. Back to the calcs...Thanks for the reality check Forrest.

-

Attachments

-

Last edited by

PyroJoe on Wed Feb 10, 2010 5:15 am, edited 1 time in total.

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Wed Feb 10, 2010 5:03 am

PyroJoe wrote:...Thanks for the reality check Forrest.

Happy to help out ... sorry to create more work for you to do.

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Wed Feb 10, 2010 4:18 pm

No worries,

for some reason I always try to run before walking. Will try to break this beasty into sections more useful.

The first inclination to working through this was the idea that there should be a terminal velocity of sorts, where the thrust of an engine will become equal to the drag force.

As Grey pointed out, the exhaust velocity is important here, as the vehicle/jet velocity won't increase past the exhaust velocity. I think few scenarios will reach that territory.

Most builders measure thrust statically with a fish scale, so it would be meaningful to work static thrust against drag and rolling resistance. For better or worse thats where I started.

Last edited by

PyroJoe on Wed Feb 10, 2010 7:10 pm, edited 1 time in total.

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Wed Feb 10, 2010 5:14 pm

Finding Drag Force:

If we have coefficient of drag and frontal area, it should be possible to find the drag force for specific velocity.

(note on line 60 I arbitrarily plugged in 300 to end the loop)

Using the formula for drag:

Drag pounds= 1/391 x (Cd) x frontal area(ft.) x velocity^2 (m.p.h.)

10 INPUT "Drag Coefficient "; Cd

20 INPUT "Frontal Area of vehicle in sq. feet "; Frontarea

30 LET dragforce = (1 / 391 * Cd * Frontarea * velocity^2)

40 print "velocity mph="; velocity ; " dragforce in pounds=";dragforce

50 let velocity = velocity + 1

60 if velocity= 300 then goto 100

70 goto 30

100 end

example run:

shows "velocity mph=267 dragforce in pounds=100.35668"

We should be seeing a steep increase in drag force as the velocity increases

-

Attachments

-

-

- run1.txt

- (14.86 KiB) Downloaded 328 times

Last edited by

PyroJoe on Wed Feb 10, 2010 7:37 pm, edited 10 times in total.

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Wed Feb 10, 2010 6:11 pm

Adding Rolling Resistance:

A problem that often plagues most PJ vehicles is the initial rolling resistance. If the thrust is lower than the initial resistance the vehicle will not move.

The uninitiated will often blame the jet as being under powered, when it is often unfavorable conditions that keep the vehicle at a stand still.

Using the scales, one can do a pull against the loaded vehicle and get some idea of the initial resistance. In truth, the resistance changes depending on stuff like tire width/height inflation pressure, bearings/vehicle weight, rim type and supports, road surface type, velocity etc. etc. etc..........

For a very simple compensation, will be using static pull figures for rolling resistance. Below is the same program as above, with rolling resistance added on lines 25 and 30

10 INPUT "Drag Coefficient "; Cd

20 INPUT "Frontal Area of vehicle in sq. feet "; Frontarea

25 INPUT "Rolling Resistance "; RR

30 LET dragforce = (1 / 391 * Cd * Frontarea * velocity^2) + RR

40 print "velocity mph="; velocity ; " dragforce in pounds=";dragforce

50 let velocity = velocity + 1

60 if velocity= 300 then goto 100

70 goto 30

100 end

example run with 29 pounds input as rolling resistance:

shows "velocity mph=225 dragforce in pounds=100.267052"

notice how the drag force now begins at 29 pounds

-

Attachments

-

-

- run2.txt

- (14.29 KiB) Downloaded 342 times

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Wed Feb 10, 2010 8:50 pm

In using the terminal velocity theory, the force of drag will bring the force of thrust into balance somwhere in the 225mph range, something I'm not completely sold on yet.

Finding Acceleration

If the vehicle weight is known and the force propelling the vehicle is known, then one can find acceleration by:

F=M*A

Rewritten as A=F/M

Acceleration(ft./sec^2) = Force / Mass(in slugs)

Applied in line 60

10'one slug = 32.174 pounds mass

20 LET slug = 32.174

30 INPUT "Total craft weight "; weight

40 INPUT "Engine thrust "; thrust

50 LET slugweight = weight / slug

60 LET accel = thrust / slugweight

70 PRINT "acceleration= "; accel; "ft/sec^2"

80 END

example run using 1500 pounds for the vehicle, and 100 pounds thrust for the engine:

Total craft weight 1500

Engine thrust 100

acceleration= 2.14493333ft/sec^2

(Notice that there is no account for the forces of drag involved, this will become an issue)

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Thu Feb 11, 2010 4:02 am

Awaiting the main code modifications ...

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Fri Feb 12, 2010 2:09 pm

Still working on it, it seems to run with constant acceleration ok, but when I try to alter the acceleration the results are poor.

I've tried two techniques, the first was to simply subtract the drag force from the thrust force before calculating acceleration. The second was to create a second acceleration using drag force, then subtract that acceleration from the constant acceleration.

I did see velocity arc a few times, but the velocity didn't plateau at the velocity it should have.

So...still working at it.

-

Attachments

-

- mph arc

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Fri Feb 12, 2010 10:28 pm

I can help you here.

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Fri Feb 12, 2010 11:07 pm

Thanks,

Help would be much appreciated, I've tried to read more about non-uniform acceleration, but sources tends to shift the focus onto a constant or re-shuffle into derivatives.

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Sun Feb 14, 2010 5:57 am

Well, let's start at the beginning with an

fbd, or free body diagram.

The three forces act on the vehicle in different directions and cause an acceleration in the x-direction, which is shown here as the D'Alembert force, the -tive of the mass times acceleration ( m · d²x/dt²). The single and double dots over the x signify the 1st and 2nd derivatives of x with respect to time (a.k.a. velocity and acceleration).

Note: I used Xfig for the drawing.

-

WebPilot

- Posts: 3716

- Joined: Tue Dec 07, 2004 6:51 pm

- Antipspambot question: 0

- Location: 41d 1' N 80d 22' W

Post

by WebPilot » Sun Feb 14, 2010 4:41 pm

Now one sums the forces in the x-direction (I've presently neglected the y ones, so the problem is one dimensional) and set the sum to zero.

∑ F

x = 0

F

thrust - F

friction - F

drag - m · d²x/dt² = 0

re-arranging

m · d²x/dt² + F

drag + F

friction = F

thrust

remembering the drag is proportional to the square of the velocity

F

drag = ½ · ρ · A · (dx/dt)² · C

d

substituting this into the above, we finally get the equation of motion of the vehicle

m · d²x/dt² + ½ · ρ · A · C

d· (dx/dt)² + F

friction = F

thrust

Perhaps the reader is unaware, but in determining this expression

- we have neglected to incorporate any effects due to the reduction in mass and

- we will assume the frictional loads and thrust are constant.

PS Joe, if my first set of test runs for my computer simulation holds true, then you will have to scrap the idea of using a 100 lbf pulse-jet and move to a 500 lbf'er for a 1500 lbm vehicle. It just takes too long to accelerate otherwise.

-

PyroJoe

- Posts: 1743

- Joined: Wed Aug 29, 2007 5:44 pm

- Antipspambot question: 125

- Location: Texas

Post

by PyroJoe » Sun Feb 14, 2010 7:12 pm

Forrest,

I also had problems with the run taking to long, I trimmed the vehicle weight down to 500 pounds and kept the 100 pounds of thrust. Also the Cd could be lowered to .09

That should shorten the time per run.

To the other extreme, for light objects accelerated quickly, had to adjust the time increments from 1 second divisions to 0.1 second divisions for the output to show useful results. I think one example had a acceleration time of 4 seconds. Just something I noticed while working with it.

Joe